Silk Screen Printing

The custom paper box below is a silk screen printed book mailer, which is printed inside and out.

Custom paper box with the screen printing

What is Silk Screen Printing?

The screen printing is also referred to as silkscreen printing because silk was used initially to make the mesh at the early stage. Afterward, polyester was invented to replace the silk to improve the printing quality and to reduce the cost. Currently, the polyester is the most popular mesh in general use. Other materials include nylon and stainless steel. In the printing of the custom paper box, the mesh size is an important factor, which will determine the outcome and look of the finished design on the material.

The screen printing process on the custom paper box

The Process of the Screen Printing

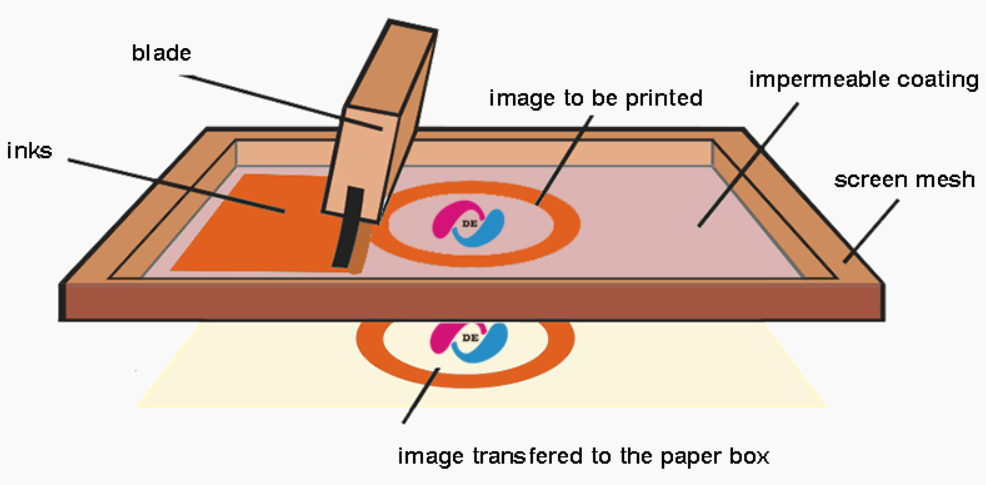

The screen printing consists of 2 main steps, prepare the screen mask, then do the printing.

- A screen mesh is stretched across an aluminum or wooden frame that matches the size of the printed paper box.

- A coating of photosensitive substance is applied on the screen mesh.

- A positive mask is used to cover the parts to be printed such as the texts and images, and then the screen mesh are exposed to the UV light. The coating on the blank parts not to be printed become hard.

- When the screen mesh is flushed with water, the coating on the printing part is washed away.

- Once the mesh is dried and inspected, the screen mask is complete.

- The screen mesh is placed on top of the paper box to be printed.

- The ink is applied across over the screen and the ink passes into the small openings on the mesh.

- The mesh touches the surface of the paper box momentarily and transfers the ink to the paperboard by moving a blade or squeegee across the mesh.

Vantage Point of Screen Printing

Because the ink is forced to pass through the openings on the screen mesh to transfer the image during the screen printing process, the ink layer on the paper box would be quite thick. It means that the screen printing can be applied on any kinds of paperboard, thick or thin, glossy or matte, with a smooth or rough surface.

Custom Screen Printed Paper Box

Custom Screen Printed Paper Box